Product Classification

Automatic control of production line

Ceramic plate pneumatic feeding system

Rubber ingredients automation production line

The company produced product

Contact us

Tellphone:0086-21-57577060

Fax: 4006981163-11606

E-mail: cjk@vip.163.com

Website: www.conly.net.cn

Address: Jinda Road No. 7976 Fengxian District Shanghai

Chongqing office

Cellphone: 13508352346

Dry mortar production line

Our company designed and manufactured a variety of dry mortar production line, the past five years has more than 300 sets of dry mortar production line come into use.The current foreign companies such as basf (Germany) in China's large factories, the Santa fe building materials factory in China, domestic meichao corporation and other famous enterprises have used this company product.

Normal dry mortar production line adopts steel frame structure, typical practice is to convey raw materials (sand, cement, fly ash, additives, pigment, polymer, short fiber) to large storage silo by pneumatic conveying and bucket elevator, then dose and mix the materials from top to bottom, the mixed material is final product. The final product is packaged by packaging machine or transported to customers by bulk tanker. It usually needs to equip sand drier for the large output.

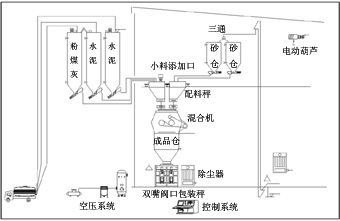

High-level steel-frame type is the typical structure of normal dry mortar production line(picture one): the features are as follows: materials conveyed to large silo directly, top-to-bottom layout, raw material silo-weighing hopper– mixer- finished product silo- packaging machine, all the equipment run automatically and are controlled by computer and instrument, because of the high accuracy, many large enterprises prefer to use this production line.

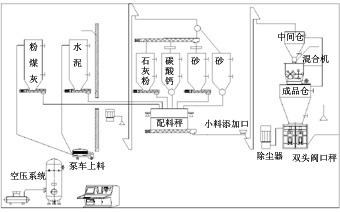

Layered steel-frame structure production line(picture two): The material in the silo is conveyed to weighing scale on the ground by screw conveyer, and discharged after weighing, then conveyed to mixer by bucket elevator, discharged to finish product hopper after mixing, and finally packaged by packaging machine. This production line can low the investment, and workers don’t need operate on the platform.

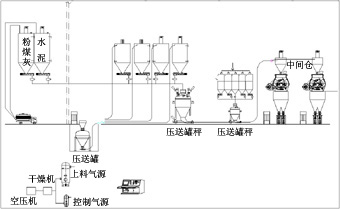

The pneumatic conveying system(picture three) is widely used in mortar plant for the following features: large capacity output, low residual and low dust. There is a weighing pot (patent design) under the large silos, the various materials is conveyed to mixer after weighing by air pressure, then to the mixer, finish product hopper, and finally packaged by packaging machine. The patent is approved in 2011.

Certifications

|

|

| Invention in 1982 | Patent in 2010 |

|

|

| Wen Wei Po In 1990 |

Patent in 1989 |

|

|

| Patent in 1988 | Patent in 1989 |